| The scope of work | |

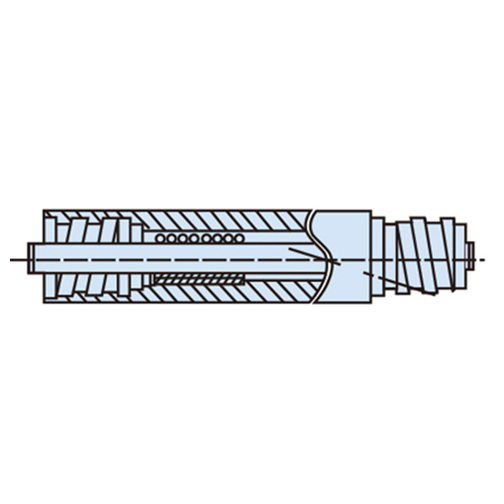

| Drilling diameter range | Φ40~Φ80mm |

| Maximum boring diameter | Φ200mm |

| Maximum boring depth | 1-5m |

| Nesting diameter range | Φ50~Φ140mm |

| Spindle part | |

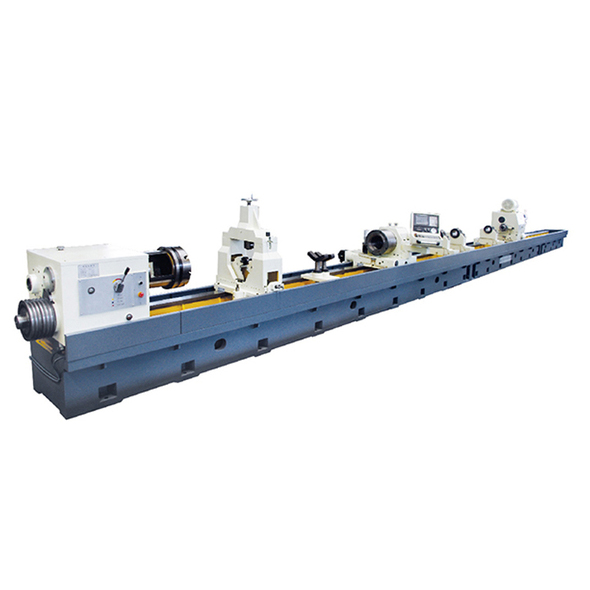

| Spindle center height | 350mm/450mm |

| Drill pipe box part | |

| Taper hole at the front end of the drill pipe box | Φ100 |

| Taper hole at the front end of the spindle of the drill pipe box | Φ120 1:20 |

| Spindle speed range of the drill pipe box | 82~490r/min; level 6 |

| Feed part | |

| Feed speed range | 5-500mm/min; stepless |

| Fast moving speed of pallet | 2m/min |

| Motor part | |

| Drill pipe box motor power | 30kW |

| Fast moving motor power | 4 kW |

| Feed motor power | 4.7kW |

| Cooling pump motor power | 5.5kWx2 |

| Other parts | |

| Rail width | 650mm |

| Rated pressure of cooling system | 2.5MPa |

| Cooling system flow | 100, 200L/min |

| Worktable size | Determined according to workpiece size |

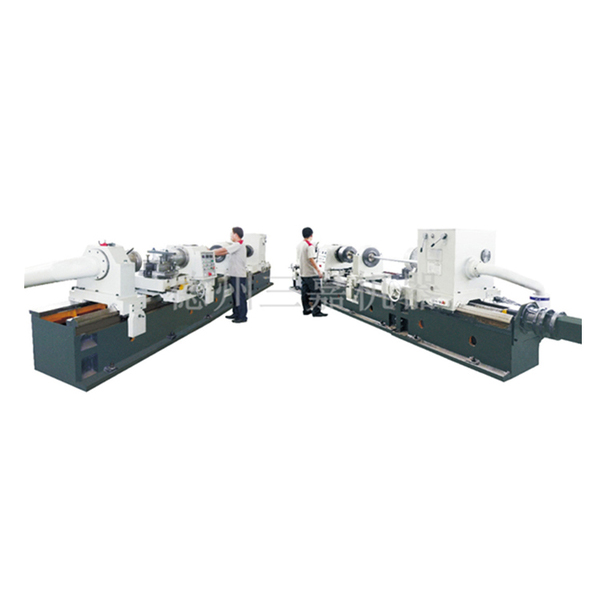

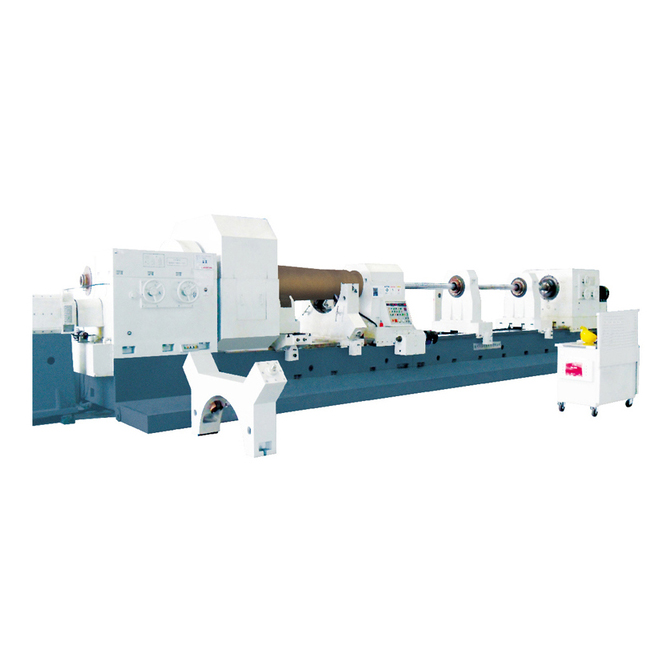

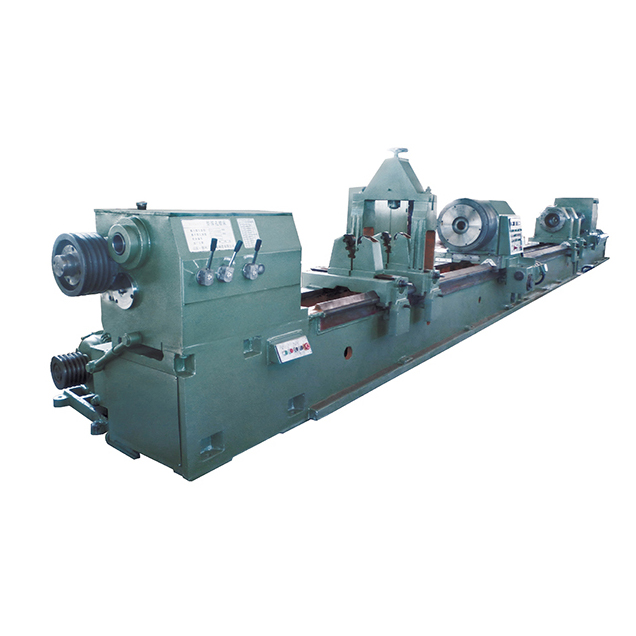

In addition, the TS2120E special-shaped workpiece deep hole machining machine is designed with durability and service life in mind. The machine's robust construction and high-quality components guarantee reliable operation even under challenging working conditions. With regular maintenance and proper care, this machine will last and provide excellent value for money. ● Specially process special-shaped deep hole workpieces. ● Such as processing various plates, plastic molds, blind holes and stepped holes, etc. ● The machine tool can undertake drilling and boring processing, and the internal chip removal method is used when drilling. ● The machine bed has strong rigidity and good accuracy retention. ● This machine tool is a series of products, and various deformed products can be provided according to customer needs.

In addition, the TS2120E special-shaped workpiece deep hole machining machine is designed with durability and service life in mind. The machine's robust construction and high-quality components guarantee reliable operation even under challenging working conditions. With regular maintenance and proper care, this machine will last and provide excellent value for money. ● Specially process special-shaped deep hole workpieces. ● Such as processing various plates, plastic molds, blind holes and stepped holes, etc. ● The machine tool can undertake drilling and boring processing, and the internal chip removal method is used when drilling. ● The machine bed has strong rigidity and good accuracy retention. ● This machine tool is a series of products, and various deformed products can be provided according to customer needs.