| Drilling diameter range | Φ50-Φ180mm |

| Boring diameter range | Φ100-Φ1600mm |

| Nesting diameter range | Φ120-Φ600mm |

| Maximum boring depth | 13m |

| Center height (from flat rail to spindle center) | 1450mm |

| Diameter of the four-jaw chuck | 2500mm (claws with force-increasing mechanism). |

| Spindle aperture of headstock | Φ120mm |

| Taper hole at the front end of the spindle | Φ120mm, 1;20 |

| Spindle speed range and number of stages | 3~190r/min stepless speed regulation |

| Main motor power | 110kW |

| Feed speed range | 0.5~500mm/min (AC servo stepless speed regulation) |

| Fast moving speed of carriage | 5m/min |

| Drill pipe box spindle hole | Φ100mm |

| Taper hole at the front end of the spindle of the drill rod box | Φ120mm, 1;20. |

| Drill rod box motor power | 45kW |

| Spindle speed range and level of drill pipe box | 16~270r/min 12 grades |

| Feed motor power | 11kW (AC servo stepless speed regulation) |

| Cooling pump motor power | 5.5kWx4+11 kWx1 (5 groups) |

| Hydraulic pump motor power | 1.5kW, n=1440r/min |

| Rated pressure of cooling system | 2.5MPa |

| Cooling system flow | 100, 200, 300, 400, 700L/min |

| Load capacity of machine tool | 90t |

| The overall dimensions of the machine tool (length x width) | About 40x4.5m |

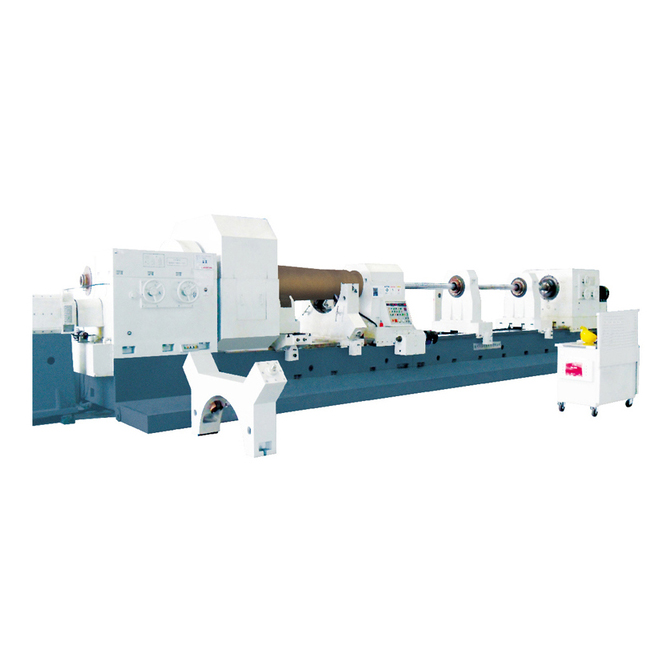

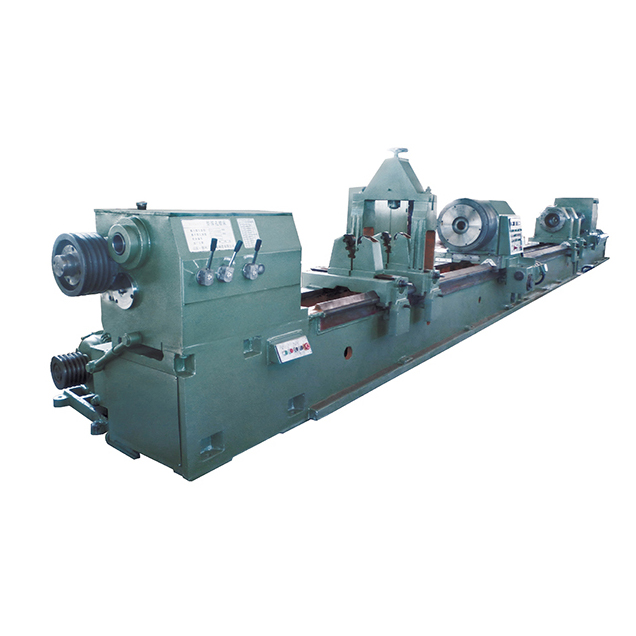

TS21160X13M heavy-duty deep hole drilling and boring machine

Looking for a heavy-duty deep hole drilling and boring machine? Choose our TS21160X13M! As a factory, we ensure top-quality products and efficient performance.

Request a QuotePRODUCTS DETAILS

Hot Products

TS2120 TS2135 TS2150 TS2250 TS2163 deep hole drilling and boring machine

TS2116 deep hole drilling and boring machine

TLS2210A /TLS2220B deep hole drawing boring machine

TS2180 TS2280 TSQ2180 TSQ2280deep hole drilling and boring machine

TS2225 TS2235 deep hole boring machine

2MSK2125/2MSK2135 CNC powerful honing machine

2MSK2150/2MSK2180/2MSK21100 deep hole powerful honing machine

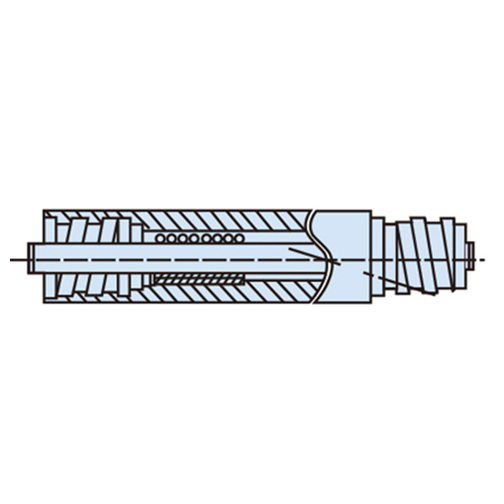

Honing rod

ZJ type machine clamp indexable BTA deep hole drill

ZSK2104E CNC Deep Hole Drilling Machine

Contact us

Please feel free to give your inquiry in the form below We will reply you in 24 hours