| The scope of work | |

| Drilling diameter range | Φ60~Φ180mm |

| Maximum diameter of boring hole | Φ1000mm |

| Nesting diameter range | Φ150~Φ500mm |

| Maximum boring depth | 1-20m (one size per meter) |

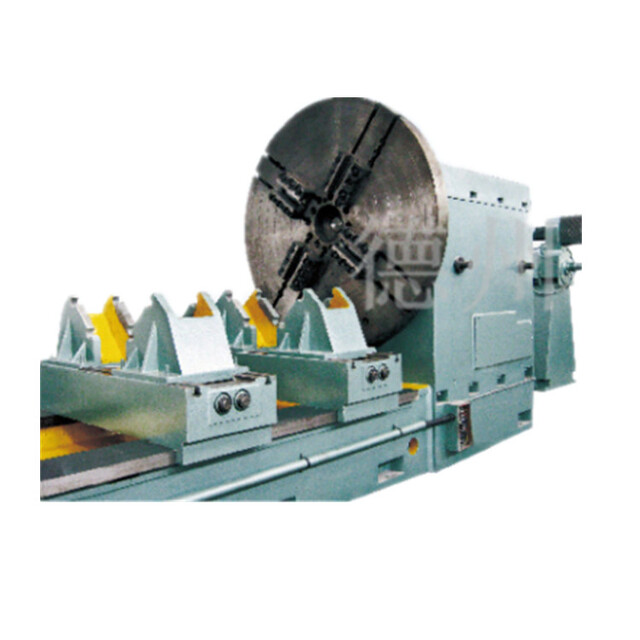

| Chuck clamping diameter range | Φ270~Φ2000mm |

| Spindle part | |

| Spindle center height | 1250mm |

| Conical hole at the front end of the bedside box | Φ120 |

| Taper hole at the front end of the headstock spindle | Φ140 1:20 |

| Spindle speed range of headbox | 1~190r/min; 3 gears stepless |

| Feed part | |

| Feed speed range | 5-500mm/min; stepless |

| Fast moving speed of pallet | 2m/min |

| Motor part | |

| Main motor power | 75kW |

| Hydraulic pump motor power | 1.5kW |

| Fast moving motor power | 7.5 kW |

| Feed motor power | 11kW |

| Cooling pump motor power | 11kW+5.5kWx4 (5 groups) |

| Other parts | |

| Rail width | 1600mm |

| Rated pressure of cooling system | 2.5MPa |

| Cooling system flow | 100, 200, 300, 400, 700L/min |

| Rated working pressure of hydraulic system | 6.3MPa |

| The oil applicator can withstand the maximum axial force | 68kN |

| The maximum tightening force of the oil applicator to the workpiece | 20 kN |

| Drill pipe box part (optional) | |

| Taper hole at the front end of the drill pipe box | Φ120 |

| Taper hole at the front end of the spindle of the drill pipe box | Φ140 1:20 |

| Spindle speed range of the drill pipe box | 16~270r/min; 12 levels |

| Drill pipe box motor power | 45KW |

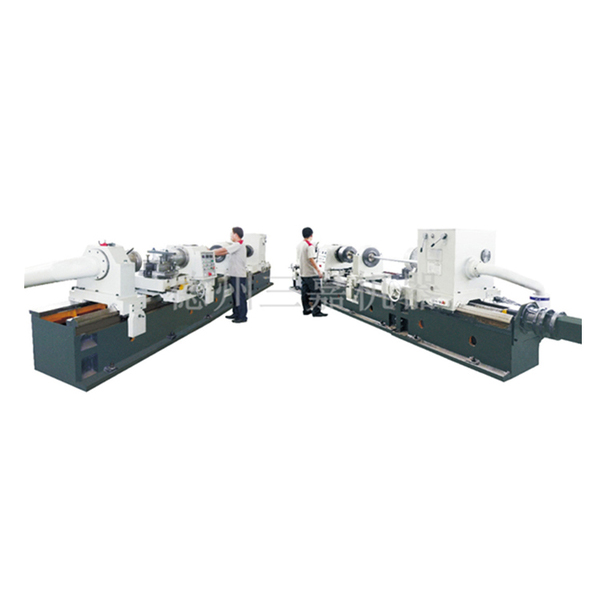

TS21100/TS21100G/TS21160 heavy-duty deep hole drilling and boring machine

Introducing our TS21100/TS21100G/TS21160 Heavy-Duty Deep Hole Drilling and Boring Machine. We are a factory specializing in manufacturing and delivering superior quality equipment globally.

Request a QuotePRODUCTS DETAILS

Hot Products

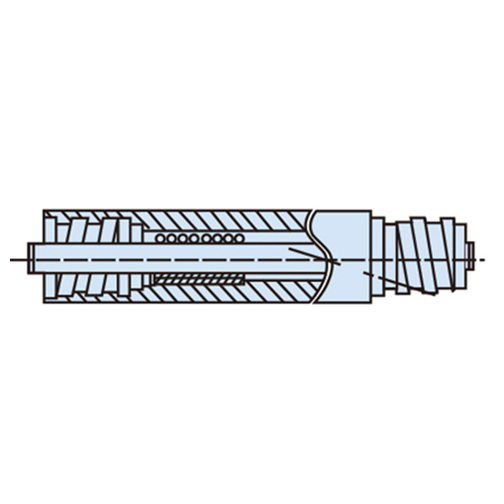

ZJ type machine clamp indexable BTA deep hole drill

TS2120E type special-shaped workpiece deep hole processing machine tool

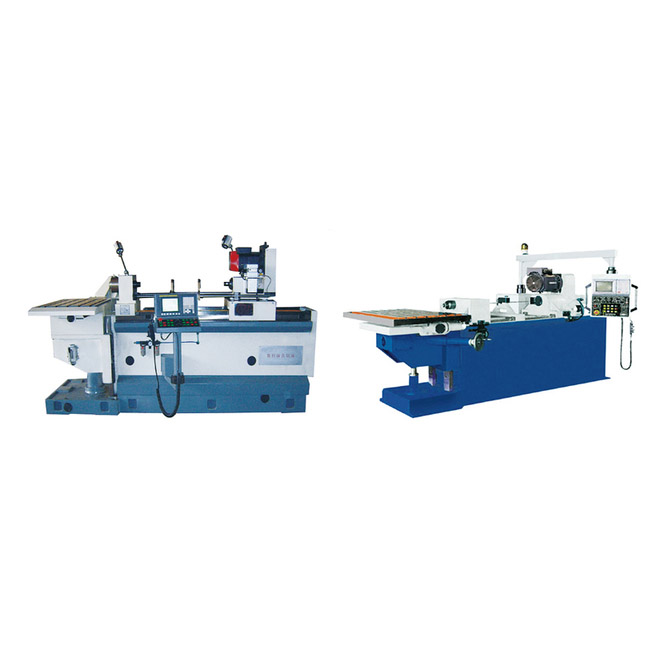

TGK25/TGK35 CNC deep hole boring and scraping machine

ZSK21 series CNC deep hole drilling machine

2MSK2125/2MSK2135 CNC powerful honing machine

ZSK2302/ ZSK2303 Three-axis CNC Deep Hole Drilling Machine

Honing rod

TS2120 TS2135 TS2150 TS2250 TS2163 deep hole drilling and boring machine

ZSK2104E CNC Deep Hole Drilling Machine

JT/TJ type deep hole fine boring head

Contact us

Please feel free to give your inquiry in the form below We will reply you in 24 hours