Essential Guide to Engine Block Bore Machines: What You Need to Know

By:Admin

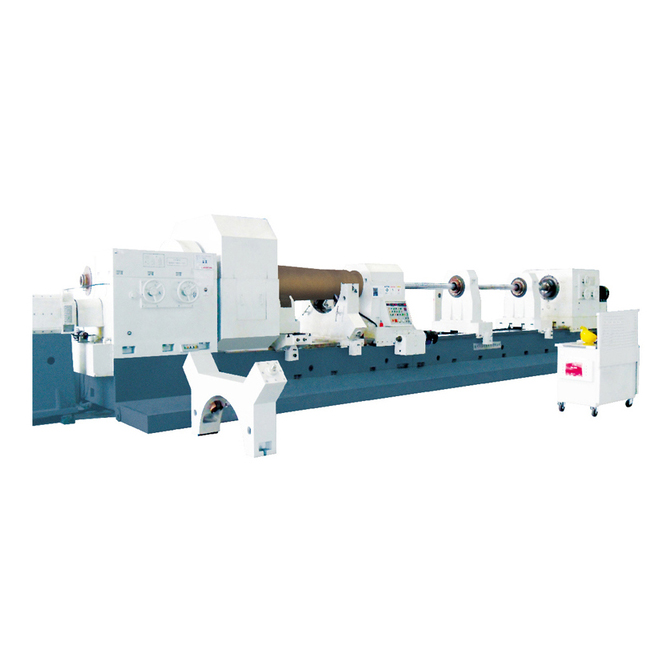

In today's rapidly evolving world of manufacturing and engineering, precision and efficiency are paramount. With the demand for high-performance engines on the rise, companies are constantly seeking innovative solutions to improve the quality and accuracy of their products. This is where the Engine Block Bore Machine comes into play - a cutting-edge piece of equipment that is set to revolutionize the way engine blocks are manufactured.

At the forefront of this technological advancement is {Company Name}, a leading provider of precision engineering solutions. With a strong focus on innovation and customer satisfaction, {Company Name} has been a trusted name in the industry for over 20 years. Their commitment to quality and excellence has earned them a reputation for delivering top-of-the-line products that meet the highest standards.

The Engine Block Bore Machine is the latest addition to {Company Name}'s impressive lineup of precision engineering equipment. Utilizing state-of-the-art technology, this machine is designed to deliver unparalleled accuracy and consistency in the machining of engine blocks. Its advanced features make it a game-changer in the industry, allowing for faster production times and superior end results.

One of the key advantages of the Engine Block Bore Machine is its ability to perform precise bore machining with unmatched efficiency. This is made possible by its advanced control system, which enables the machine to maintain tight tolerances and produce smooth, clean bores with minimal operator intervention. As a result, manufacturers can expect a significant reduction in scrap rates and a substantial increase in productivity.

Furthermore, the machine's versatility allows it to accommodate a wide range of engine block sizes and configurations, making it suitable for various applications across different industries. Whether it's for automotive, marine, or industrial engines, the Engine Block Bore Machine is capable of handling the most demanding machining tasks with ease.

In addition to its advanced capabilities, the Engine Block Bore Machine is designed with user-friendly features that make it easy to operate and maintain. Its intuitive interface and streamlined workflow ensure that operators can quickly familiarize themselves with the machine and maximize its performance. Moreover, its robust construction and durable components guarantee long-term reliability and minimal downtime.

As part of {Company Name}'s commitment to customer satisfaction, the Engine Block Bore Machine is backed by comprehensive support services. From installation and training to ongoing maintenance and technical assistance, customers can rely on {Company Name} to provide the expertise and resources needed to optimize the performance of their equipment.

The introduction of the Engine Block Bore Machine underscores {Company Name}'s dedication to pushing the boundaries of precision engineering and empowering manufacturers to achieve new levels of excellence. With its unmatched capabilities and unwavering reliability, this machine is poised to set a new standard for engine block machining and solidify {Company Name}'s position as a leader in the industry.

In conclusion, the Engine Block Bore Machine represents a significant leap forward in the realm of precision engineering. Its advanced technology, versatility, and user-friendly design make it a valuable asset for manufacturers seeking to elevate the quality and efficiency of their engine block machining processes. As the latest innovation from {Company Name}, this machine is a testament to their unwavering commitment to delivering cutting-edge solutions that empower their customers to succeed in a competitive marketplace.

Company News & Blog

Compact Honing Machine for Precise Sharpening

Small Honing Machine has recently been introduced by a leading company in the manufacturing industry. The new machine, which boasts a compact design and advanced features, is set to revolutionize the honing process for a wide range of industries.The Small Honing Machine is designed to be versatile and efficient, making it an ideal solution for manufacturers who require precision honing for a variety of components. The machine is capable of honing a wide range of materials, including steel, aluminum, and ceramic, making it suitable for use in diverse industrial applications.One of the key features of the Small Honing Machine is its compact design, which allows for easy integration into existing manufacturing processes. This makes it an ideal choice for manufacturers who are looking to improve the efficiency and quality of their honing operations without having to invest in costly equipment upgrades.In addition to its compact design, the Small Honing Machine also boasts advanced features that set it apart from traditional honing equipment. These features include a high-performance honing head, precision control system, and advanced monitoring capabilities, all of which contribute to the machine's ability to deliver precise and consistent results.The company behind the Small Honing Machine has a proven track record of delivering high-quality manufacturing solutions to a wide range of industries. With decades of experience in the field, the company has established itself as a leading provider of innovative and reliable manufacturing equipment.The introduction of the Small Honing Machine is a testament to the company's commitment to staying at the forefront of technological advancements in the manufacturing industry. By continually investing in research and development, the company is able to bring cutting-edge solutions to market that address the evolving needs of manufacturers.The Small Honing Machine is just the latest example of the company's dedication to innovation and excellence. By listening to the feedback and requirements of its customers, the company has been able to develop a machine that meets the highest standards of quality and performance.The introduction of the Small Honing Machine is expected to have a significant impact on the manufacturing industry, as it will enable manufacturers to improve the quality and consistency of their honing processes. With its advanced features and compact design, the machine is poised to become a go-to solution for companies looking to enhance their honing operations.In conclusion, the Small Honing Machine introduced by the company represents a major advancement in the field of honing technology. With its compact design, advanced features, and proven track record of quality and reliability, the machine is set to make a big impression on the manufacturing industry. As manufacturers continue to seek out innovative solutions to improve their processes, the Small Honing Machine is well-positioned to meet their needs and exceed their expectations.

High-Quality Honing Machine for Precision Engine Component Finishing

Standard Honing Machine Launches New Innovation in Precision Machining{Company Name} is proud to announce the launch of their latest innovation in precision machining - the Standard Honing Machine. This cutting-edge machine is set to revolutionize the industry by providing unparalleled accuracy and efficiency in honing processes.The Standard Honing Machine is designed to meet the demands of modern manufacturing, offering a wide range of capabilities to meet the diverse needs of the industry. Equipped with advanced technology and state-of-the-art features, this machine is capable of delivering high-precision honing with exceptional consistency and repeatability.With a focus on quality and reliability, {Company Name} has integrated their years of experience and expertise into the development of the Standard Honing Machine. The result is a product that sets a new standard for precision machining, offering superior performance and unmatched accuracy.The key features of the Standard Honing Machine include:- Advanced control system for precise and automated honing processes- High-performance spindle for enhanced stability and vibration control- Flexible tooling options to accommodate a wide range of honing applications- Intuitive interface for easy operation and monitoring- Robust construction for long-term durability and reliabilityThe Standard Honing Machine is a testament to {Company Name}'s commitment to innovation and excellence. With a dedication to delivering cutting-edge solutions to the industry, the company has continually invested in research and development to stay ahead of the competition."We are thrilled to introduce the Standard Honing Machine to the market," said {Company Name} CEO. "This machine represents a significant milestone for our company and our customers. We believe that it will redefine the standards for precision machining and provide our customers with a competitive edge in their operations."The launch of the Standard Honing Machine comes at a time when the manufacturing industry is seeking advanced solutions to improve productivity and efficiency. With its advanced capabilities, this machine is poised to address the evolving needs of the industry and set new benchmarks for performance and quality in honing processes.{Company Name} has a strong track record of delivering innovative solutions to the manufacturing industry. With a focus on customer satisfaction and continuous improvement, the company has earned a reputation for excellence and reliability in its products and services.As the demand for precision machining continues to grow, {Company Name} is well-positioned to meet the needs of the industry with the introduction of the Standard Honing Machine. With its cutting-edge technology and exceptional performance, this machine is set to become a game-changer in the field of honing and precision machining.In summary, the launch of the Standard Honing Machine signifies a new era in precision machining, with {Company Name} at the forefront of innovation and excellence. This machine is set to redefine the standards for honing processes, offering unmatched accuracy, efficiency, and reliability to the industry. As the manufacturing industry continues to evolve, {Company Name} remains committed to driving progress and delivering advanced solutions to meet the evolving needs of its customers.

The Benefits of Deep Hole Honing for Precision Machining

Deep Hole Honing is a specialized machining process that is used to improve the geometric form and surface finish of bores and holes in various materials. The process involves the use of abrasive stones, tools, and fine-grit abrasives to remove small amounts of material from the internal surface of the bore or hole.Deep Hole Honing is commonly used in the automotive, aerospace, defense, and medical industries for applications such as hydraulic cylinder tubes, gun barrels, engine blocks, and medical implants. The process can improve the dimensional accuracy, roundness, and straightness of bores, as well as achieve the desired surface finish, such as a cross-hatched pattern, that is critical for proper lubrication and sealing.One company that has excelled in the field of Deep Hole Honing is {}. Established over 30 years ago, {} has been a leader in providing precision honing solutions for a wide range of industries. The company's commitment to quality, innovation, and customer satisfaction has made it a trusted partner for companies seeking reliable and efficient deep hole honing services.{}'s deep hole honing capabilities include the ability to hone bores with diameters as small as 1.5mm up to 500mm, with lengths of up to . Their state-of-the-art honing machines and proprietary honing processes allow them to achieve tight tolerances and superior surface finishes, meeting the most demanding specifications and requirements of their clients.The company's team of highly skilled and experienced engineers and technicians are dedicated to providing custom honing solutions that meet the unique needs of each customer. Whether it's a small batch of prototypes or a large-scale production run, {} has the expertise and resources to deliver consistent, high-quality honed parts on time and within budget.{}'s commitment to quality is further demonstrated by their adherence to rigorous quality control measures and certifications, including ISO 9001. This ensures that every honed component that leaves their facility meets the highest standards of precision and performance.In addition to deep hole honing, {} offers a comprehensive range of complementary machining services, including boring, turning, milling, and grinding. The company's ability to provide a one-stop-shop for all machining needs makes them a valuable partner for customers looking for a reliable and efficient source for precision components.With a focus on continuous improvement and investment in the latest honing technology, {} remains at the forefront of the deep hole honing industry. The company's dedication to innovation and staying ahead of industry trends allows them to offer cutting-edge solutions that meet the evolving needs of their customers.As the demand for precision-engineered components continues to grow across various industries, {} remains poised to meet the challenges and deliver superior deep hole honing services that exceed expectations. With a track record of success and a commitment to excellence, {} continues to be a trusted provider of precision honing solutions for companies seeking to achieve the highest levels of quality and performance in their machined components.

Top-Notch Hone Ki Machine Exclusively for You!

In today's fast-paced world, the demand for convenient and efficient home appliances is on the rise. With the increasing reliance on technology to simplify our daily tasks, the need for innovative solutions has never been greater. This is where the latest innovation in home appliances, the Hone Ki Machine, comes into play.The Hone Ki Machine is a revolutionary new product that is set to change the way we think about home maintenance. This state-of-the-art machine is designed to streamline the honing process for a variety of household items, making it easier than ever to keep your home in top condition. From kitchen knives and gardening tools to scissors and other sharp objects, the Hone Ki Machine is able to sharpen and maintain a wide range of items with ease.One of the key features of the Hone Ki Machine is its user-friendly design. With easy-to-follow instructions and a simple interface, this innovative appliance is accessible to users of all skill levels. Whether you're a seasoned professional or a complete novice, the Hone Ki Machine makes honing and sharpening a hassle-free experience.Furthermore, the Hone Ki Machine is equipped with advanced technology that ensures precision and accuracy in every honing task. Its cutting-edge sharpening system is capable of restoring the sharpness of blades and edges, giving your household items a new lease of life. This high level of performance is achieved through a combination of innovative engineering and premium materials, making the Hone Ki Machine a reliable and efficient tool for any home.In addition to its impressive functionality, the Hone Ki Machine is also designed with safety as a top priority. The machine is equipped with safety features that prevent accidents and injuries, providing peace of mind for users. With its durable construction and smart design, the Hone Ki Machine is a reliable and secure addition to any home.The company behind the Hone Ki Machine, {}, is a leader in the field of home appliances and innovative solutions. With a strong reputation for quality and performance, {} has a track record of delivering cutting-edge products that enhance the lives of consumers. The Hone Ki Machine is the latest example of their commitment to excellence, offering a solution that meets the needs of modern households.{} has established itself as an industry leader through a combination of expert craftsmanship and innovative technology. Their dedication to research and development has resulted in products that are not only effective, but also user-friendly and efficient. These values are evident in the Hone Ki Machine, which reflects {}'s ongoing commitment to providing practical and reliable solutions for the modern home.As the demand for convenient and efficient home appliances continues to grow, the Hone Ki Machine is poised to make a significant impact in the market. Its advanced features, user-friendly design, and commitment to safety have already garnered attention from consumers and industry experts alike. With {}'s reputation for excellence behind it, the Hone Ki Machine is set to become a must-have for households looking to simplify their honing and sharpening tasks.In conclusion, the Hone Ki Machine is an exciting new addition to the world of home appliances. With its innovative features, user-friendly design, and commitment to safety, it represents a significant leap forward in the field of honing and sharpening solutions. Supported by the industry-leading expertise of {}, the Hone Ki Machine is set to redefine the way we think about home maintenance, offering a practical and efficient solution for households everywhere.

Advanced Four-Axis CNC Deep Hole Drilling Machine Unveiled in Latest News

Title: Advanced Four-Axis CNC Deep Hole Drilling Machine Revolutionizes Industrial ManufacturingIntroduction:In recent breakthrough news, a pioneering Four-Axis CNC Deep Hole Drilling Machine has been unveiled by a cutting-edge industrial machinery company. With its innovative design and state-of-the-art technology, this groundbreaking machine promises to revolutionize the manufacturing industry. Leveraging precision engineering and advanced automation, this deep hole drilling machine offers unparalleled efficiency, accuracy, and versatility for a wide range of industrial applications.1. Enhanced Precision and Accuracy:Utilizing advanced four-axis technology, this new CNC deep hole drilling machine pushes the boundaries of precision machining. The intricate drilling process is executed with exceptional accuracy, ensuring optimal performance in demanding industries such as aerospace, automotive, and energy. The machine utilizes high-precision linear guides and spindle drives, resulting in precise and stable drilling operations. This cutting-edge technology reduces human error, enhancing the overall quality of the finished product.2. Unmatched Efficiency:The integration of intuitive software and automation in this Four-Axis CNC Deep Hole Drilling Machine streamlines the manufacturing process, drastically reducing production time. The machine features a user-friendly interface, allowing operators to easily program and control drilling parameters. The advanced automation capabilities enable constant monitoring and adjustment, minimizing downtime and maximizing productivity. This results in improved manufacturing efficiency and reduced costs for businesses.3. Versatility in Machining Applications:The new four-axis CNC deep hole drilling machine caters to a diverse range of industrial applications, thanks to its adaptable nature. From drilling complex parts to creating shallow holes with high precision, this machine can handle a wide variety of materials, including metal, alloy, and composite materials. Additionally, its four-axis capability ensures the machining of complex parts with intricate geometries, expanding its usefulness across different industries.4. Intelligent Cooling System:The CNC deep hole drilling machine incorporates an intelligent cooling system that helps dissipate heat for prolonged operation. This innovative feature prevents component damage caused by overheating, ensuring extended machine life and reducing maintenance and repair costs. The cooling system also enhances the drilling process by efficiently removing chips and debris, maintaining superior drilling performance throughout the operation.5. Commitment to Quality and Reliability:The company behind the Four-Axis CNC Deep Hole Drilling Machine has built credibility and trust through its commitment to delivering high-quality industrial machinery. With years of industry experience, the company prioritizes stringent quality control measures to ensure that their products meet the highest standards. The machine undergoes rigorous testing to guarantee optimum durability, reliability, and customer satisfaction.6. Positive Industry Implications:The introduction of the Four-Axis CNC Deep Hole Drilling Machine provides a transformative solution for various industries. By improving drilling precision, streamlining processes, and reducing production time, this cutting-edge machine enhances manufacturing capabilities, facilitating technological advancements, and ultimately leading to cost-effective and high-quality end products.Conclusion:The unveiling of the Four-Axis CNC Deep Hole Drilling Machine marks a significant milestone in the manufacturing industry. With its enhanced precision, unbeatable efficiency, and versatility in machining applications, this groundbreaking machine holds tremendous potential to revolutionize industrial manufacturing. By combining advanced technology, automation, and a commitment to quality and reliability, the company behind this innovative machinery is poised to make a significant impact in the market, paving the way for future advancements and driving overall industry growth.

DIY Cylinder Honing Machine: A Budget-Friendly Option for Engine Maintenance

Home-based mechanics and small engine repair shops have a new tool in their arsenal with the introduction of the Homemade Cylinder Honing Machine, a cost-effective and efficient solution for honing engine cylinders.The Homemade Cylinder Honing Machine is designed and manufactured by an innovative company that specializes in creating practical and affordable tools for mechanics and hobbyists. With a dedication to quality and precision, they have developed a honing machine that can rival professional-grade equipment at a fraction of the cost.This new machine is perfect for small engine repair shops or DIY enthusiasts who want to hone engine cylinders without breaking the bank. It is compact and easy to use, making it a valuable addition to any workshop or garage. The homemade design allows for customization, giving users the ability to modify and improve the machine to suit their specific needs.The Homemade Cylinder Honing Machine is constructed from durable materials, ensuring longevity and reliability. The company takes pride in providing customers with tools that are built to last, and this honing machine is no exception. It is a solid investment for anyone looking to hone engine cylinders on a regular basis.One of the key features of this honing machine is its versatility. It is compatible with a wide range of engine sizes, making it a versatile tool for mechanics who work on various types of engines. Whether it's motorcycles, small cars, or lawnmowers, the Homemade Cylinder Honing Machine can handle the job with ease.Furthermore, the company offers excellent customer support and technical assistance to ensure that customers are able to use the honing machine properly and achieve the best results. They are committed to providing a positive user experience, and that includes offering guidance and advice for novice users.The Homemade Cylinder Honing Machine is also designed with safety in mind. The company understands the importance of protecting users from potential hazards, and they have incorporated safety features into the design of the honing machine. This gives users peace of mind while working with the equipment, knowing that they are protected from harm.In addition to its practicality and affordability, the Homemade Cylinder Honing Machine is also environmentally friendly. It reduces the need for outsourcing cylinder honing work, which can result in lower carbon emissions and fuel consumption. This aligns with the company's commitment to sustainability, making the honing machine a responsible choice for conscientious mechanics and hobbyists.As an added bonus, the company provides a warranty for the Homemade Cylinder Honing Machine, giving customers added assurance that they are investing in a reliable and well-supported tool. This is a strong demonstration of the company's confidence in their product, and it gives customers the confidence to invest in the honing machine without hesitation.Overall, the Homemade Cylinder Honing Machine is a game-changer for small engine repair shops and home-based mechanics. With its affordability, versatility, durability, and commitment to user safety and support, it is a standout tool in the world of engine repair equipment. The company behind this innovative machine has once again proven their dedication to providing practical and affordable tools for mechanics, and the Homemade Cylinder Honing Machine is a testament to their ingenuity and commitment to quality.

High-Performance Drilling Machine for Gun Barrels Available Now

Gun Barrel Drilling Machine Revolutionizes Firearms ManufacturingGun manufacturing has undergone a revolutionary transformation with the introduction of the latest state-of-the-art Gun Barrel Drilling Machine by a leading industrial machinery company. The cutting-edge technology of this innovative machine has set a new standard in precision and efficiency for the production of firearm barrels.The Gun Barrel Drilling Machine, developed by the company's team of expert engineers and designers, has revolutionized the way in which gun barrels are manufactured. This advanced machine is capable of drilling precise and uniform bores in a wide range of firearm barrels, ensuring exceptional accuracy and consistency in the production process.The company's commitment to continuous innovation and improvement is evident in the development of this groundbreaking Gun Barrel Drilling Machine. With its advanced features and unparalleled precision, this machine has significantly enhanced the quality and performance of firearm barrels, setting a new benchmark for the industry.One of the key features of the Gun Barrel Drilling Machine is its ability to drill and ream barrels with utmost precision, resulting in superior bore quality and alignment. This level of accuracy is crucial in ensuring that each firearm barrel meets the highest standards for performance and reliability.Furthermore, the machine's advanced automation and control systems enable it to operate with exceptional speed and efficiency, significantly reducing the production time for firearm barrels. This not only improves the overall productivity of firearm manufacturing but also allows for a more streamlined and cost-effective production process.In addition to its remarkable precision and efficiency, the Gun Barrel Drilling Machine is also designed with versatility in mind. It is capable of drilling a wide range of barrel sizes and configurations, making it suitable for the production of various types of firearms, including rifles, shotguns, and handguns.The company's dedication to excellence and innovation has earned it a reputation as a leader in the industrial machinery industry. With a strong focus on research and development, the company continues to push the boundaries of technology to deliver cutting-edge solutions that meet the evolving needs of its customers.The introduction of the Gun Barrel Drilling Machine is a testament to the company's commitment to providing the firearms industry with innovative and game-changing manufacturing solutions. By leveraging the latest advancements in engineering and automation, the company has undoubtedly set a new standard for precision and efficiency in firearm barrel production.The company's success in developing the Gun Barrel Drilling Machine is a result of its relentless pursuit of excellence and its unwavering dedication to exceeding customer expectations. With a proven track record of delivering high-quality industrial machinery, the company has firmly established itself as a trusted partner for manufacturers in the firearms industry.In conclusion, the introduction of the Gun Barrel Drilling Machine marks a significant milestone in the evolution of firearm manufacturing. With its unprecedented precision, efficiency, and versatility, this cutting-edge machine has set a new benchmark for the production of firearm barrels, solidifying the company's position as a leader in the industrial machinery industry. As the firearms industry continues to evolve, the company remains at the forefront, driving innovation and delivering solutions that empower manufacturers to achieve new levels of quality and performance.

High-Precision Deep Hole Drilling Machine in Action

The deep hole drilling machine, also known as the gun drilling machine, is a precision tool that is used to create holes that are deeper than they are wide in a variety of materials. These holes are typically needed in applications such as manufacturing of oil and gas industry components, medical instruments, and automotive parts.The deep hole drilling process requires a high level of precision and accuracy, and it is often used in the production of components that require complex and intricate holes. The drilling machine is equipped with a long drill bit that is able to create holes with a diameter as small as 1mm and a depth of up to 5 meters.One of the leading manufacturers of deep hole drilling machines, {} is known for their innovative and high-quality products. With over 30 years of experience in the industry, {} has been committed to providing their customers with reliable and efficient drilling solutions.The deep hole drilling machine from {} is equipped with advanced technology and features that allow for high precision drilling. The machine operates with a combination of rotation and pressure, allowing for smooth and accurate drilling of deep holes in a variety of materials including steel, aluminum, and plastic.In addition to their state-of-the-art drilling machines, {} also provides comprehensive customer support and service. Their team of experienced engineers and technicians are available to provide training, technical support, and maintenance services to ensure that their customers are able to maximize the performance of their drilling machines.With a focus on continuous innovation and improvement, {} has been at the forefront of developing new technologies and techniques for deep hole drilling. Their commitment to research and development has allowed them to stay ahead of the competition and provide their customers with cutting-edge drilling solutions.In recent news, {} has announced the launch of their latest deep hole drilling machine, the {} 5000. This new addition to their product line is designed to further improve the efficiency and precision of deep hole drilling. With enhanced features and capabilities, the {} 5000 is expected to set new standards in the industry.“We are thrilled to introduce the {} 5000 to the market,” said the spokesperson for {}. “This new machine represents the culmination of years of research and development, and we are confident that it will exceed the expectations of our customers.”The {} 5000 is designed to handle a wide range of drilling requirements, from small scale production to large scale industrial applications. With its advanced control system and high-speed drilling capabilities, this machine is capable of producing deep holes with unparalleled accuracy and speed.The launch of the {} 5000 is a testament to {}'s commitment to providing their customers with the best deep hole drilling solutions. By combining their expertise in the industry with innovative technology, {} continues to be a leading provider of drilling machines for various industries.With the introduction of the {} 5000, {} is poised to further establish their position as a pioneer in the deep hole drilling industry. Their dedication to quality, reliability, and customer satisfaction sets them apart as a trusted and preferred partner for businesses seeking high precision drilling solutions.

Revolutionary Drilling Tool: Harnessing Advanced Technology for Unmatched Efficiency

Bta Drilling Tool Revolutionizes the Oil and Gas IndustryIn a world where efficiency and precision are paramount, Bta Drilling Tool has emerged as a game-changer in the oil and gas industry. With a firm commitment to innovation and cutting-edge technology, Bta Drilling Tool has revolutionized the way drilling operations are conducted. Their state-of-the-art tools, backed by decades of research and development, have elevated the industry standard to new heights, making drilling processes safer, faster, and more cost-effective.Founded in {year}, Bta Drilling Tool is a leading global provider of drilling equipment and solutions. Their extensive product portfolio caters to a wide range of drilling requirements, including oil and gas exploration, geothermal energy extraction, and mining operations. The company prides itself on its ability to deliver customized drilling solutions tailored to meet the unique needs of each customer, ensuring maximum productivity and efficiency.At the core of Bta Drilling Tool's success lies their steadfast commitment to pushing boundaries and exceeding expectations. Through continuous research and development, their team of experts has been able to develop some of the industry's most advanced drilling tools. From diamond core bits to downhole motors, Bta Drilling Tool has meticulously designed every product to deliver top-notch performance, durability, and reliability.One of the company's groundbreaking achievements is the development of their patented drilling technology known as {technology name}. This innovative technology has redefined the drilling process by significantly reducing drilling time while maintaining precision and accuracy. By optimizing the hydraulic system and improving the efficiency of drilling fluid circulation, Bta Drilling Tool's {technology name} ensures seamless drilling operations, thus saving time and resources for their customers.Moreover, Bta Drilling Tool's commitment to sustainability sets them apart from their competitors. Recognizing the need for environmentally-friendly drilling practices, the company has incorporated several eco-friendly features into their drilling tools. For instance, their advanced filtration systems help minimize the discharge of harmful drilling fluids into the environment, ensuring that natural habitats and water sources remain protected. This dedication to environmental stewardship has earned Bta Drilling Tool a reputation as a socially responsible and sustainable industry leader.Furthermore, Bta Drilling Tool has solidified its position as a global leader through strategic partnerships with major oil and gas companies. By collaborating with industry giants, Bta Drilling Tool gains access to invaluable expertise and resources, enabling them to develop cutting-edge solutions that address the evolving demands of the industry. These partnerships have also facilitated the exchange of knowledge and best practices, resulting in improved drilling techniques and increased operational efficiency.As the demand for energy continues to rise, Bta Drilling Tool remains at the forefront of the industry, constantly innovating and adapting to meet the evolving needs of their customers. With a dedicated team of engineers and technicians, the company is committed to staying ahead of the curve by investing in research and development. This commitment ensures that Bta Drilling Tool's customers always have access to the latest technology and solutions, empowering them to achieve their drilling objectives with utmost precision and efficiency.In conclusion, Bta Drilling Tool has revolutionized the oil and gas industry with its cutting-edge drilling solutions. Through innovative technologies such as {technology name}, the company has transformed the way drilling operations are conducted, making them safer, faster, and more cost-effective. With a commitment to sustainability and strategic partnerships, Bta Drilling Tool continues to lead the way in driving the industry forward. As the energy landscape continues to evolve, Bta Drilling Tool stands ready to meet the challenges and embrace the opportunities that lie ahead.

Compact Honing Machine: A Handy Tool for Precision Work

Small Honing Machine Revolutionizes Precision MachiningPrecision machining is a critical process in the manufacturing industry that requires the highest level of accuracy and efficiency. With the advancement of technology, the demand for precision machining has grown exponentially, leading to the development of innovative tools and machines to meet these requirements. One such innovation is the Small Honing Machine, a groundbreaking tool that is revolutionizing the world of precision machining.The Small Honing Machine, developed by a leading manufacturing solutions company, is a compact and versatile tool that is designed to deliver unparalleled precision and accuracy in the machining process. This innovative machine is equipped with advanced technology and state-of-the-art features that set it apart from traditional honing machines. Its compact size and ergonomic design make it easy to use and suitable for a wide range of applications, from small-scale production to large-scale industrial operations.The key to the Small Honing Machine's exceptional performance lies in its cutting-edge technology, which enables it to achieve superior precision and surface finish. Its advanced honing capabilities allow for the precise bore sizing, roundness, and straightness of a wide range of materials, including steel, aluminum, and various alloys. This level of precision is essential in industries such as automotive, aerospace, and medical manufacturing, where even the smallest deviations can compromise the quality and performance of the final product.In addition to its precision capabilities, the Small Honing Machine is also known for its speed and efficiency. Its high-performance motor and cutting tools enable it to achieve fast and accurate results, reducing machining time and increasing productivity. This is a significant advantage for manufacturers looking to optimize their production processes and meet tight deadlines without compromising on quality.Another standout feature of the Small Honing Machine is its user-friendly interface and intuitive controls. The machine is designed to be easy to operate, with simple setup and programming procedures that require minimal training. This accessibility allows operators to quickly familiarize themselves with the machine and start using it to its full potential, reducing downtime and maximizing efficiency.The Small Honing Machine's impact goes beyond its technical capabilities; it also represents a shift towards more sustainable and cost-effective machining practices. Its compact size and energy-efficient operation contribute to lower energy consumption and reduced carbon footprint, aligning with the industry's growing focus on environmental responsibility and resource efficiency.Furthermore, the Small Honing Machine is backed by a comprehensive support and service network offered by the manufacturing solutions company. This includes technical assistance, maintenance programs, and spare parts availability, ensuring that customers can maximize the performance and longevity of their machines.The Small Honing Machine has already made a significant impact in the precision machining industry, earning accolades from manufacturers and engineers for its exceptional performance and reliability. Its ability to deliver unmatched precision, speed, and efficiency has set a new standard for honing machines, opening up new possibilities for manufacturers to achieve their production goals with confidence.In conclusion, the Small Honing Machine is a game-changer in the world of precision machining, offering a winning combination of cutting-edge technology, user-friendly design, and sustainable operation. As the manufacturing industry continues to evolve, this innovative machine is poised to play a pivotal role in shaping the future of precision machining.